ADOR WELDING LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ADOR WELDING LTD.

Air Plasma Cutting Equipments

PLASMACUT 25

Typical Applications :

Recommended for air plasma cutting applications of all electrically conducting sheet metal up to 25 mm thick in the industries like sheet metal fabrication, Bus and coach body building workshops, Railway and transport workshops, power stations, chemical & fertiliser plants, construction & maintenance workshops, food processing and pharmaceutical equipments using SS, scrap cutting & demolition, ship breaking etc

Ideally suitable for metal cutting applications where Oxy Acytelene cutting process is not feasible or Oxy/Acetylene gases are not available, good clean cuts with higher cutting productivity are desired

Features :

Air plasma cutting outfit with Rugged, Robust design and well established diode based power source

User friendly controls on the front panel, requires minimum training to the operator

Provided with special "Safety -Interlock" for operator protection

Light weight and flexible torch with 8 mtr long hose assembly

Saw Welding Equipments

MAESTRO 800 (F) / 1000 (F) / 1200 (F)

Features :

Twin Wire Attachment : Twin Wire Attachment is available for the Tractor as well as boom mounted welding heads. The arrangement consists of one set of each of wire drive roll and nozzle for 2 and 2.5 mm size wire to feed two wires in tandem and increase the deposition rate substantially. These arrangements is ideal for applications like cladding of hard surfaces as well as for filing weld metal in extra large size preparation grooves. Twin 2.5 mm wires can deliver up to 20% higher deposition rates than a single 5 mm wire at the same welding current and arc voltage parameters.

Fillet Welding Attachment : To enhance the usability of SAW Outfits, a Fillet Welding attachment can be provided to increase shop-floor productivity.

Spot Light Projector : This facility is especially useful for welding operations inside cylindrical jobs where a light source is required to examine the seam

Choice of Boom mounted or Tractor mounted Welding head models offered with Diode or Thyristorized Power Source

Boom mounted head comes with a choice of manual, semi – motorized and fully motorized cross slides

Programmed sequential operations of Power Source, Wire feed and carriage through built- in solid state circuitry

Twin Wire Attachment is optionally available – which helps to achieve 20% to 30% increase in Productivity

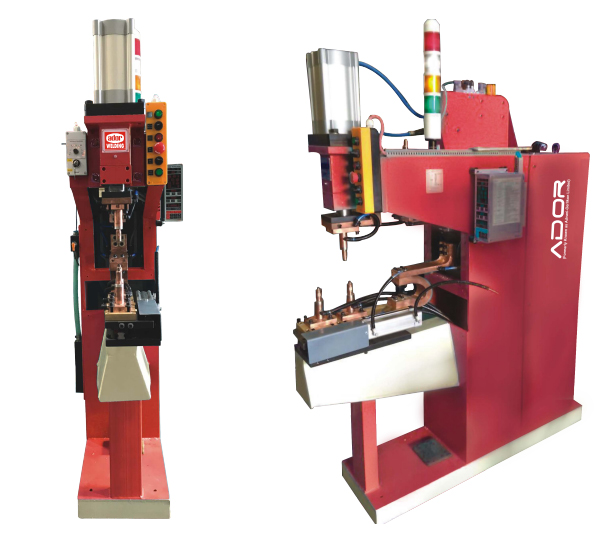

Spot Welding Machines

Stationary Projection & Spot Welding Machines & SPM's.

Features :

Electro-valve and gas cylinder are connected directly, thus increasing speed of responding and spot welding and reducing air flow cost.

Perfect pressurization speed adjustment -descending speed of the machine head pressurization can be adjusted as per requirement which softens impact and lowers noise when the workpiece is pressurized.

High strength steel performance - shoc resistant and firm.

High power SCR element is adjusted for the main loop - ensures stability and reliability.

Straight type pressing structure and high welding speed.

General Description :

Stationary Projection & Spot Welders having High Strength Robust Sturdy Pedestal type frame for high speed spot welding operation.

SPM’s Designed as per component to achieve high production rates & cycle time. Performance proved PLC, HMI, Servo Motors offered as per ratings.

Resistance Welding Controller

Description / Specification of Resistance Welding Controller

We are involved in offering a wide range of Resistance Welding Controller to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Resistance Welding Controller. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Seam Welders

Ador Seam Welders

General Description :

Seam Welders have excellent efficiency and hassle free functionality, fitted with high quality transformer, cooling system and high quality weld assembly which are corrosion and abrasion resistant.

SPM’s are designed as per components to achieve high production rates & cycle time Performance proved PLC, HMI, Servo Motors offered as per ratings.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.